Whey

Did you know that 10% of milk is used to make cheese? In this blog, we explain this and tell you more about the other 90%, namely the cheese whey

When making cheese, we use milk. To turn this milk into cheese, you heat the milk to 29-30 degrees Celsius and add ingredients such as leavening and rennet

Lactic acid bacteria are present in starter culture and convert lactose (milk sugar) into lactic acid. That lactic acid makes the cheese more acidic, lowering the pH so that the cheese curdles and keeps longer. Moreover, the lactic acid affects the taste of the cheese. That's why we have our own recipe, which gives our typical Henri Willig flavour.

Important ingredients

Nowadays, you can also get vegetarian rennet, also called microbial rennet. We only use microbial rennet for our cheeses so that our cheese is also suitable for vegetarians.

These ingredients make the milk thicken and after 30 to 45 minutes the milk is then as thick as pudding. We start cutting this thickened milk by passing slowly rotating knives through the whey. This takes about 30-45 minutes and then you can see that the liquid whey is separated from the solid curd. The curd (10%) will eventually become the cheese. So the remaining 90% is the whey and it is fortunately multi-purpose.

To hear and experience the whole story of cheese making, we encourage everyone to visit our shops and farms. There you can learn even more about it and, of course, taste our cheese!

A versatile product

Now we come back to whey and how multifunctional this product is. Whey is widely used in animal feed and has a good influence on intestinal function and resistance of calves, for example. It is also in many consumer products such as certain soft drinks, cosmetics, chocolate and even in, for example, our beer.

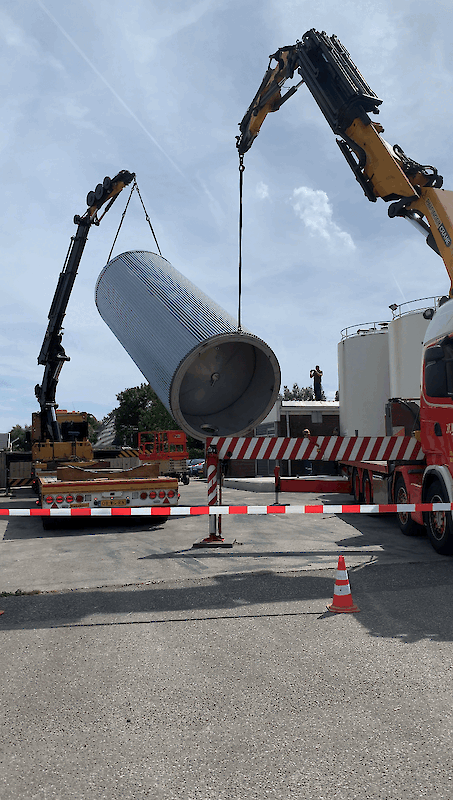

Developments in sustainability

But in its original form, it is a large volume which involves a lot of transport. That is why we now have a 'Nanofiltration system' in operation that can thicken this whey from 5% to 20% dry matter. This saves on transport costs, which is interesting for our customers and ourselves. It enables us to reduce transport movements by 30%. And thanks to this new system, we significantly reduce CO2 emissions.

In short, great developments that we are quite proud of!

Greetings, the Henri Willig Cheese Family

Is this article already making you hungry?

Check out Henri Willig's delicious recipes below.

The perfect high cheese board

The preparation method for this colourful high cheese is very simple! Supplies: Plank Cheese knife Cocktail sticks Preparation: Uncrust the cheeses and cut the cheeses into wedges Cut the fruit and vegetables into pieces/slices Decorate the cheese wedges with the fruit / vegetables Present decoratively on a board and use a cocktail stick where necessary Make the number you need of each variation, e.g. 5.

Luxury cheese board with Henri Willig family line cheeses and homemade pear balsamic jam

This cheese board is the star of the show! Method of preparation: Place the fig/balsamic dip around a central area of your board Shave nice slices of the various family line cheeses and place them nicely around the fig/balsamic dip. Then place the various cheeses all around. It's fun to cut these up in different ways, e.g. slices, cubes, slants. Place the crackers and the kletzen bread with the cheeses Cut the blood orange into slices and put them between the cheeses. Do the same with the small pieces of apple. Scatter the toasted walnuts and olives over your board Recipe ✨ Peel the pear and cut it into very small cubes. Put them in a pan with 2 tablespoons of water and simmer for 5-10 minutes on high heat. Keep stirring well! You may break up the pear pieces a little with the spoon, so it becomes a thick puree. At the last minute, add the balsamic vinegar and simmer for another 1 minute. Put the balsamic pear jam in a small jar with a small spoon and serve with your cheeseboard Thanks to @courgetticonfetti for the beautiful board and the recipe for the jam.